Timing Belts

Rear Wheel Drive Timing Belts

Product Details

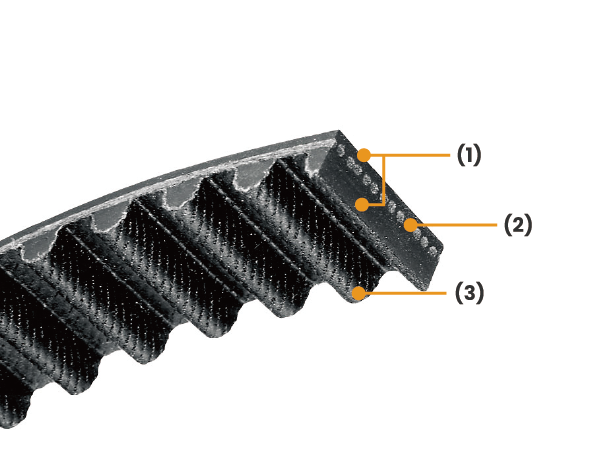

Constituent Materials

-

(1) Rubber: High rigidity rubber that can withstand high loads

(2) Tensile cord: High modulus tensile cord with low elongation

(3) Tooth fabric: Tooth fabric with excellent abrasion resistance

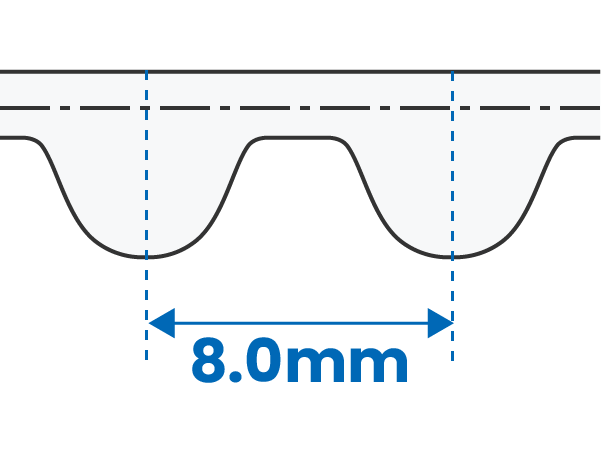

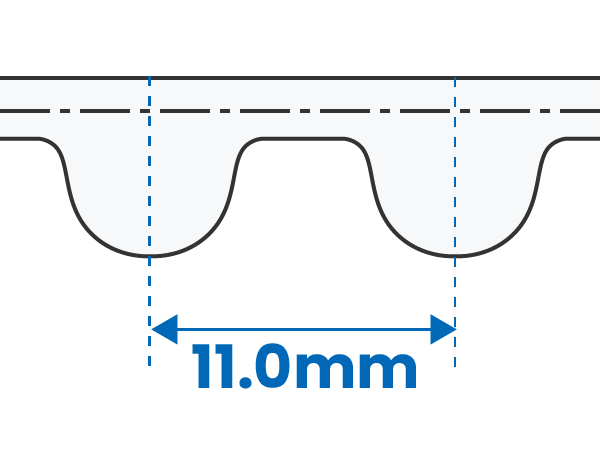

Tooth Profile

It is possible to set the tooth profile to match the layout.

(The belt and pulley must have matching tooth profiles.)

-

Tooth Profile (8.0mm)

-

Tooth Profile (11.0mm)

Features

-

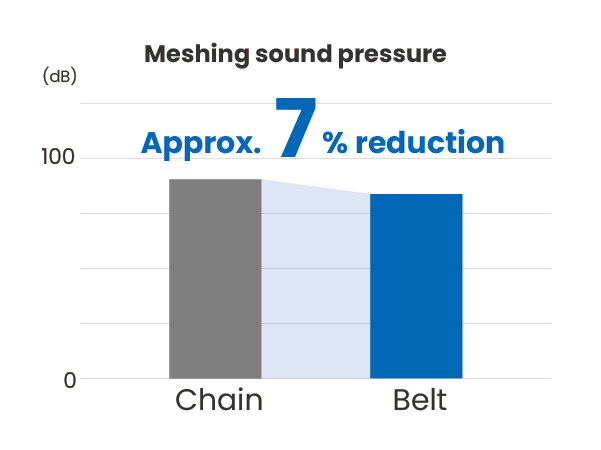

Sound pressure reduction

Compared to chains, there is a maximum reduction in sound pressure of approximately 7%.*¹

*¹ Our test results. Drive pulley rotation speed: 1000 rpm.

-

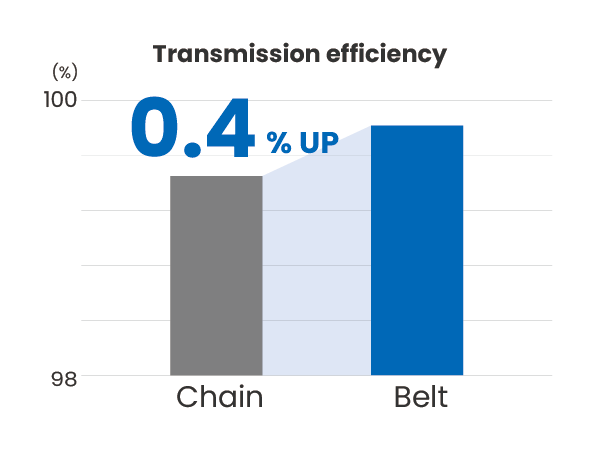

High transmission efficiency

Compared to chains, the transmission efficiency is improved by up to approximately 0.4%.*²

*² Our test results. Drive pulley rotation speed: 920 rpm.

Other advantages

| Maintenance-free | Lightweight | Long life |

|---|---|---|

|

|

|

|

No need to re-stretch or re-oil |

The belt system is approximately 10% lighter than the chain system. |

Excellent durability, contributing to reduced replacement costs |

Product Introduction Video

Noise reduction

We will introduce the technology of the rear-wheel drive belt and the reasons why it is chosen.

-

Belt drive

-

Chain drive

Transmission efficiency is improved by up to 0.4 % compared to a chain drive.(*2)

(*2) Our test results.Drive pulley speed: at 920 rpm.

-

High Transmission Efficiency