High-temperature Firing Pastes

Ag-based

Conductor pastes (Ag-based)

Product Details

Features

-

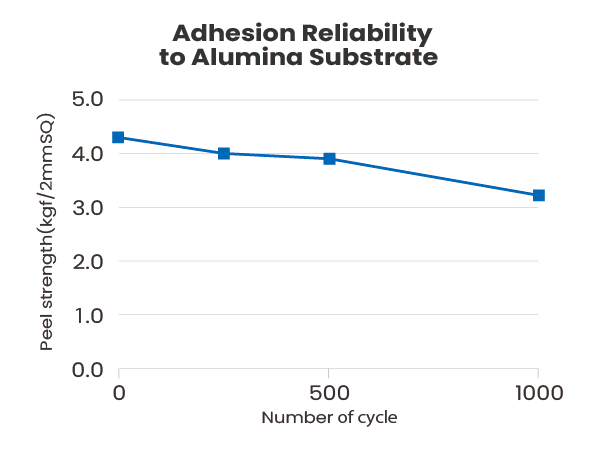

High adhesion reliability

Test Conditions

・After silver paste plating

・Thermal cycle test : -45℃⇔125℃

・Dstruction mode : in-solder destruction / substrate gouging -

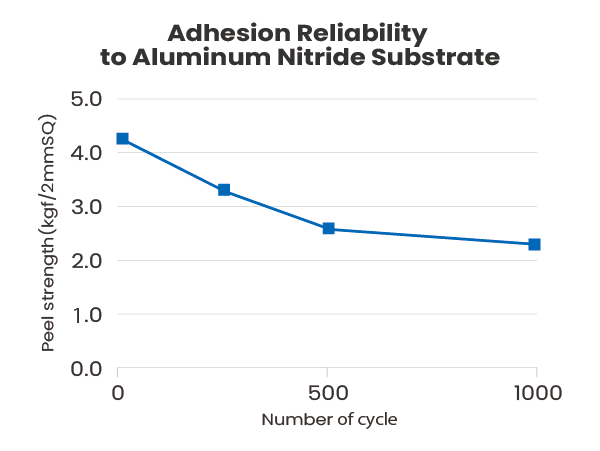

High adhesion reliability

Test Conditions

・After silver paste plating

・Thermal cycle test : -45℃⇔125℃

・Fracture mode : interfacial detachment

Application Example

-

- Wiring formation on LED mounting circuit package substrate (alumina substrate)

- Wiring formation on passive components (aluminum nitride substrate)

- Ceramic heater

Specification

| Type | Conductor component | Feature | Resistivity (μΩ・cm) | Coating method | Adhesive strength (N/2mm□) | Recommended curing/firing condition | Substrate |

|---|---|---|---|---|---|---|---|

| HS109 | Ag | Ion migration resistance, Good solderability, Nickel plateable | ≦3 | Screen printing | ≧40 | 900 °C 10min | Al₂O₃ |

| HS201 | Ag | Nickel plateable | ≦4 | Screen printing | ≧40 | 900 °C 10min | AlN |

| HS301 | Ag | Good solderability, Nickel plateable | ≦3 | Screen printing | ≧20 | 500–900 °C 10min | Glass, Al₂O₃ |

| HS102P | AgPd | Pd 2%, 5% containing, Sulfur resistance, Ion migration resistance, Nickel plateable |

Pd2% : ≦4 | Screen printing | ≧40 | 900 °C 10min | Al₂O₃ |

| Pd5% : ≦6 | Screen printing | ≧40 | 900 °C 10min | Al₂O₃ |

Caution

- The listed data represents typical values and does not guarantee performance or quality.

- Product specifications are subject to change without notice.

Remarks

We also have silver pastes for various applications. Please contact us for requests such as adjusting the coating properties.