High-temperature Firing Pastes

CuAgTi-based

Conductor pastes(CuAgTi-based)

Product Details

Features

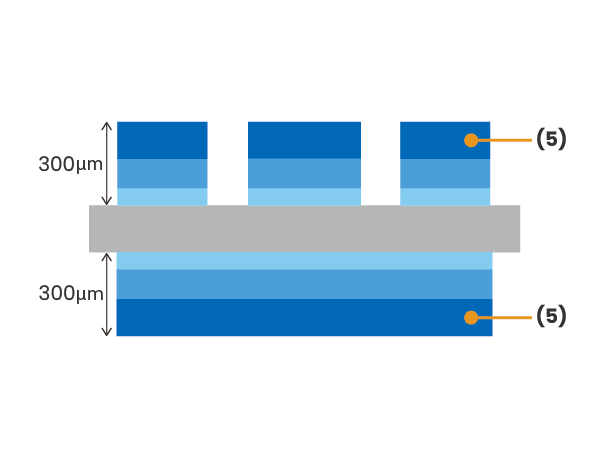

- By layering copper paste on the upper layer, it is possible to form an ultra-thick film of 0.3 mm or more.

- It does not contain environmentally hazardous substances such as Pb and Cd.

- It has excellent heat resistance, impact resistance, and reliability.

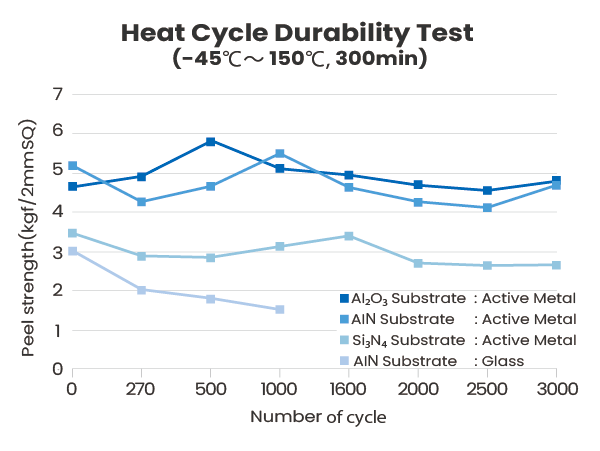

- The metal film and substrate form a strong chemical bond, providing excellent adhesion to Si₃N₄ and AlN substrates.

Structure

-

Film thickness of less than 100 μm

■Process

(1) Print the bonding layer (AS112)

(2) Print the upper layer of the bonding layer (DC014GL)

(3) Firing, e.g. 850℃, N₂ atmosphere -

Film thickness of 100 μm or more

For a film thickness of 100 μm or more, the following process is added.

■Process

(4) Print the thickening layer (GL39)

(5) Firing, e.g. 800℃, N₂ atmosphere

-

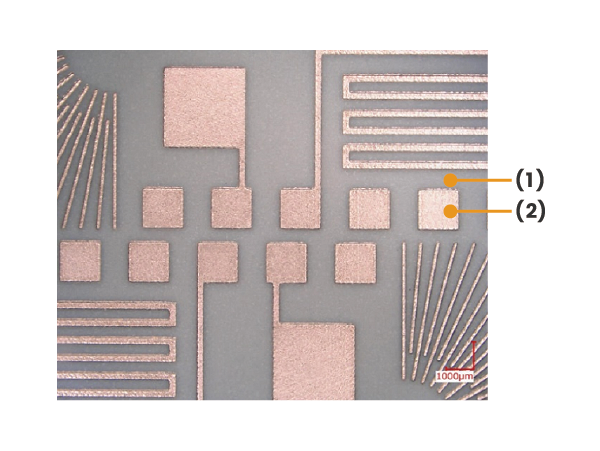

Substrate image after firing

Copper paste thick film (50μm) fired substrate using an active metal paste as the bonding layer.

(1) SiN

(2) Copper -

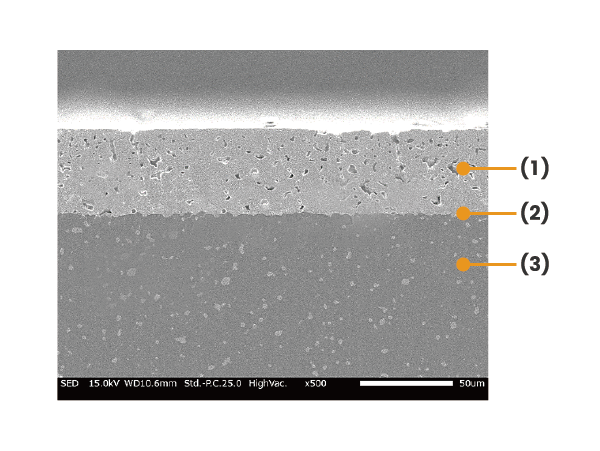

Cross-section SEM image

Substrate image after firing

(1) Copper film

(2) Active metal containing bonding layer (structural formula: Ti5Si3)

(3) SiN substrate

Application Example

-

- Ceramic heat dissipation circuit packages for power devices

- Ceramic circuit boards and ceramic packages that require high reliability

Specification

| Type | Film thickness | Application | Feature | Conductor component | Adhesive Strength (N/2mm□) | Recommended firing condition | Coating method | Substrate | |

|---|---|---|---|---|---|---|---|---|---|

| 100μm< | 100μm≧ | ||||||||

| AS112 | ○ | ○ | Thick film conductor wiring, Electrode formation (bonding layer with ceramic substrate) | High bonding strength, High thermal reliability | Ag, Cu, Ti |

≧30 |

850 °C 10min, |

Screen printing | Al₂O₃, AlN, Si₃N₄ |

| DC014GL | ○ | ○ | Thick film conductor wiring, Electrode formation | High surface smoothness, Larger film thickness can be formed in a single print | Cu | - | 850 °C 10min, In N₂ |

Screen printing | Al₂O₃, AlN, Si₃N₄ |

| GL39 | - | ○ | Ultra-thick film conductor wiring, Electrode formation(for multilayer thickening) | Larger film thickness can be formed in a single print | Cu | - | 800 °C 10min, In N₂ |

Screen printing | Al₂O₃, AlN, Si₃N₄ |

Caution

- It should be fired in a nitrogen atmosphere.

- Please check the Material Safety Data Sheet (SDS) for each product.

Remarks

If you do not have a replacement nitrogen furnace, we can fire it on your behalf.