High-temperature Firing Pastes

CuAgTi-based

Active metal pastes( CuAgTi-based) for bonding between copper plate and ceramics

Product Details

Features

-

- This paste bonds firmly to Si₃N₄ substrates, which are difficult to bond.

- It has excellent thermal shock resistance.

- It can be bonded in a continuous furnace in a nitrogen atmosphere.

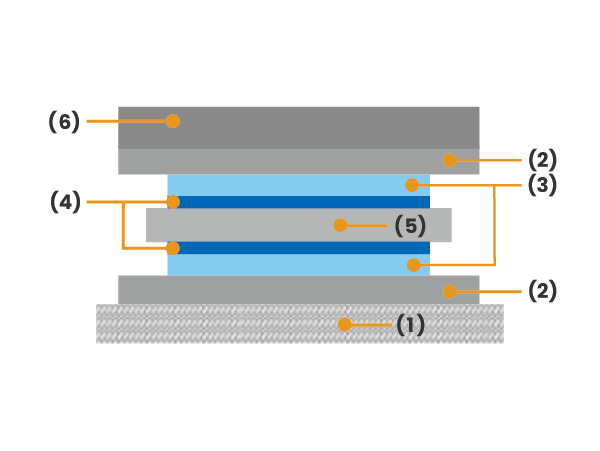

Structure

Firing example in a continuous furnace

-

Copper plate laminating using an active metal paste in the bonding layer.

(1) Mesh belt

(2) Alumina substrate

(3) Cu plate

(4) Paste

(5) Ceramic substrate

(6) Weight (40g/㎠) -

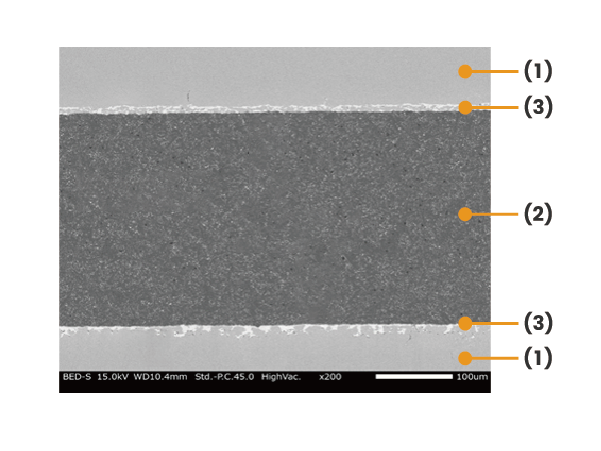

Cross-sectional SEM image

(1) Cu plate

(2) AIN substrate

(3) Bonding layer

-

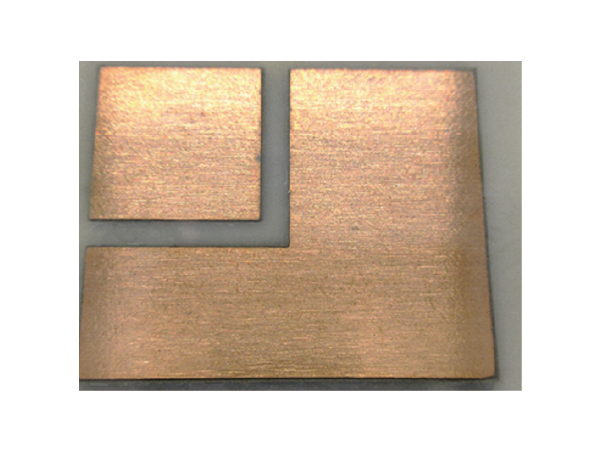

Bonding sample of copper plate and silicon nitride substrate, using active metal paste

Application Example

-

Ceramic heat-dissipating circuit packages for power devices

Specification

| Type | Application | Feature | Conductor component | Adhesive strength (N/2mm□) | Recommended firing condition | Coating method | Substrates |

|---|---|---|---|---|---|---|---|

| AS102 | Bonding between copper and ceramic substrates | High bonding strength, High thermal reliability | Ag, Cu, Ti |

≧30 | 850 °C 10min, In N₂ | Screen printing | Al₂O₃, AlN, Si₃N₄ |

Caution

- It should be fired in a nitrogen atmosphere.

- Please check the Material Safety Data Sheet (SDS) for each product.

Remarks

If you do not have a replacement nitrogen furnace, we can fire it on your behalf.