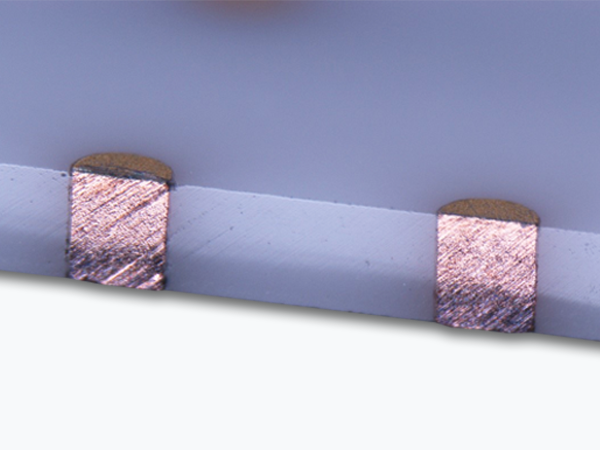

Via-filling Solutions

Via-filling substrate

Product Details

Features

-

- It has excellent reliability, precision, and heat dissipation.

- It complies with RoHS2.

- It adheres firmly to the substrate.

- The surface of the board can be finished smoothly, allowing components to be mounted directly above the filled vias.

- Uniform via filling with few voids or gaps is possible.

- It can also be used for high-airtight applications (AgCu alloy dense filling) that suppress voids and gaps.

Application Example

-

Various types of package boards and module boards that require high reliability and heat dissipation

Specification

| Substrate Material | Substrate Size*¹(inch) | Board thickness*²(mm) | Hole diameter*³(mm) | Hole diameter aspect ratio*¹ | Resistivity(μΩcm) | Filling section unevenness(No polishing) | Filling section unevenness(With lap polishing) | Section unevenness(with mirror polishing) | |

|---|---|---|---|---|---|---|---|---|---|

| Cu filling | AIN, Al₂O₃, SiN, Machinable ceramics, Sapphire, SiO₂ | 2×2~4.5×4.5 | 0.2~1.0 | 0.05~2.0 | 1.0~10.0 | 5~7 | ≦ ±30μm | ≦ ±3μm | ≦ ±1μm |

| Ag filling | AIN, Al₂O₃, SiN, Machinable ceramics, Sapphire, SiO₂ | 0.05~1.0 | 3~4 | ≦ ±30μm | ≦ ±2μm | ||||

| AgCu alloy dense filling | AIN, Al₂O₃, SiN, Machinable ceramics | 1.0~6.5 | - | Polishing is essential. |

*¹ There are exceptions depending on the hole diameter and plate thickness.

*² Please contact us for thicknesses other than those listed above.

*³ There are exceptions depending on the plate thickness.

Caution

The data and specifications above are just examples.

Remarks

Please contact us about filling vias with paste other than copper.